Article

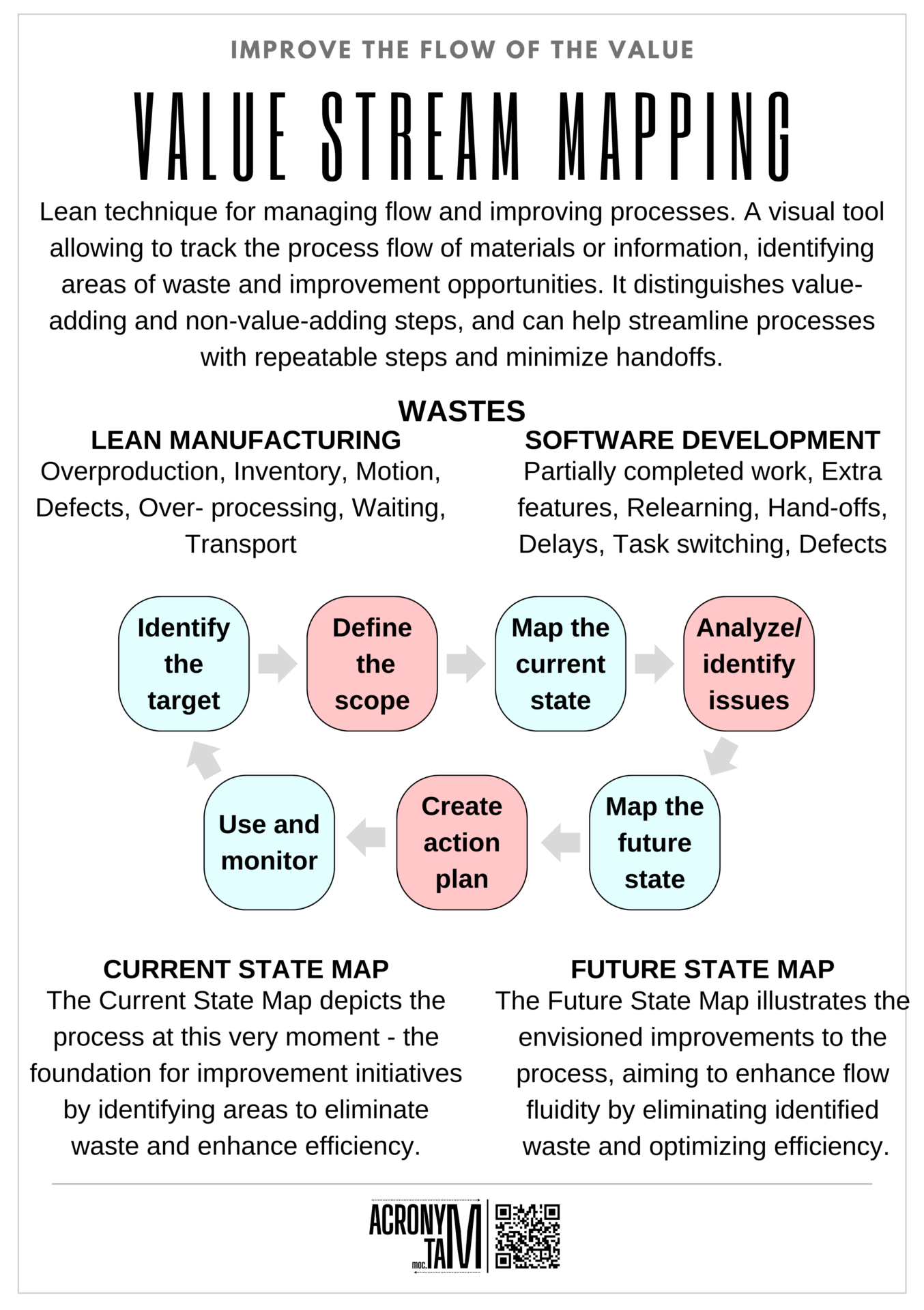

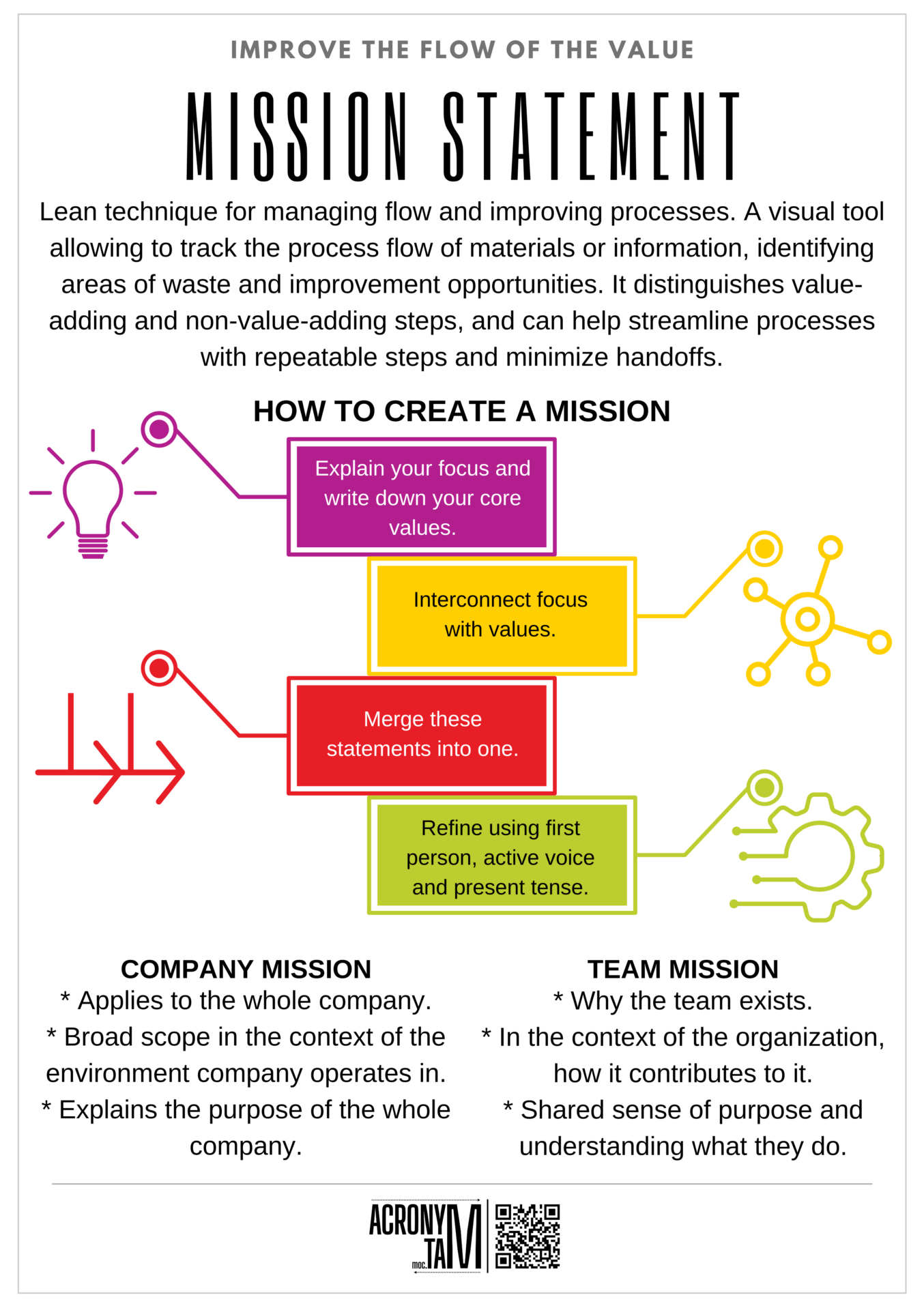

The Value Stream Mapping is a Lean technique for managing flow and improving processes. This visual tool allows us to track the flow of materials or information through a process, identifying areas of waste and opportunities for improvement. By distinguishing between value-adding and non-value-adding steps, it can help to streamline processes with repeatable steps and minimize handoffs.

Lean manufacturing wastes

- Overproduction

- Inventory

- Motion

- Defects

- Over- processing

- Waiting

- Transport

Software development wastes

- Partially completed work

- Extra features

- Relearning

- Hand-offs

- Delays

- Task switching

- Defects

Current state map

The Current State Map depicts how the process operates at this moment, serving as the foundation for improvement initiatives by identifying areas to eliminate waste and enhance efficiency.

Future state map

The Future State Map illustrates the envisioned improvements to the process, aiming to enhance flow fluidity by eliminating identified waste and optimizing efficiency.

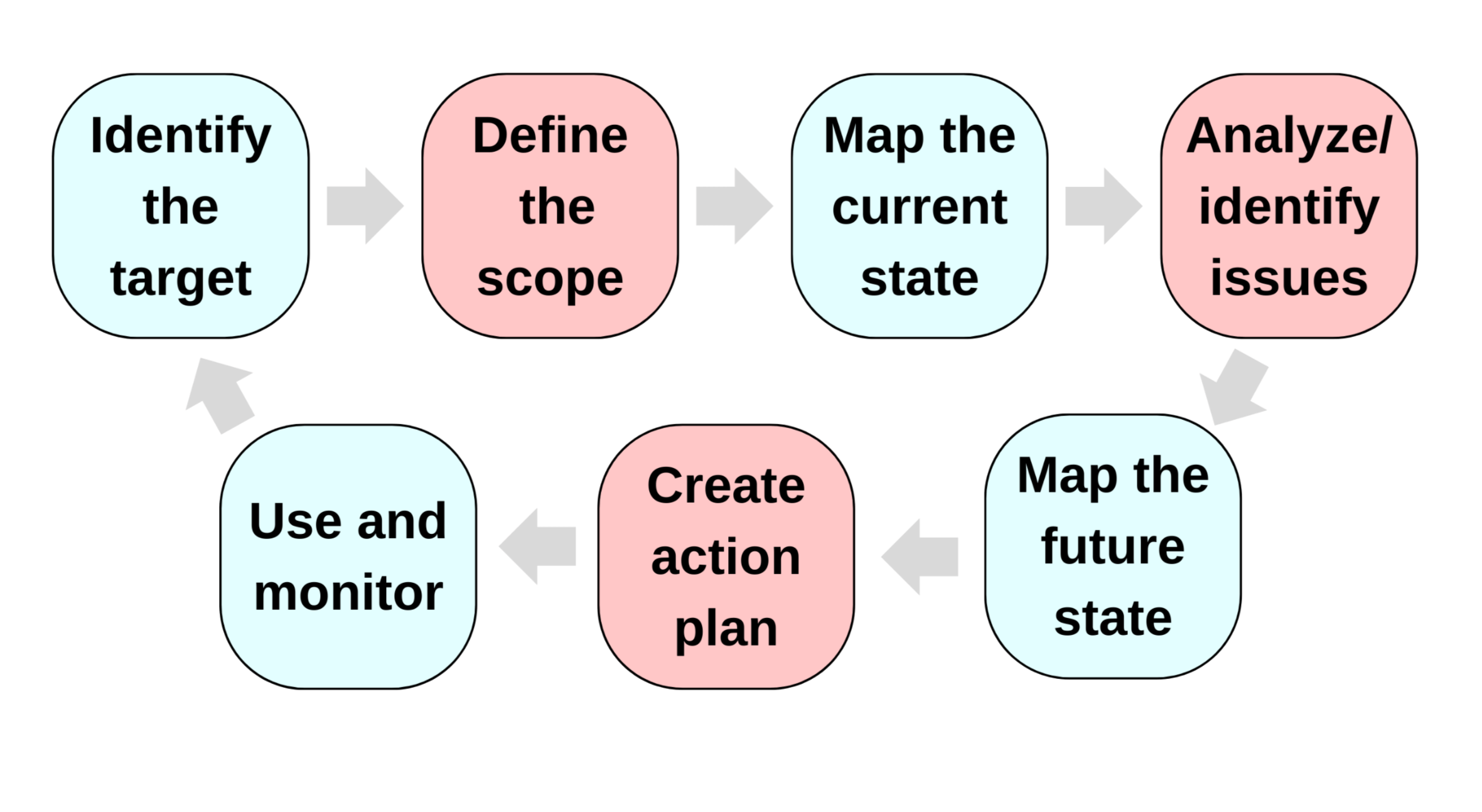

Value Stream Mapping steps

- Identify the target

- Define the scope

- Map the current state

- Analyze/identify issues

- Map the future state

- Create action plan

- Use and monitor